Mechatronic System: Olympic Robot

CAD | Mechatronics | Arduino Controls| Technical Documentation | Fabrication | Hardware/Software Testing | Product Management

A Summary in Photos

Project Overview

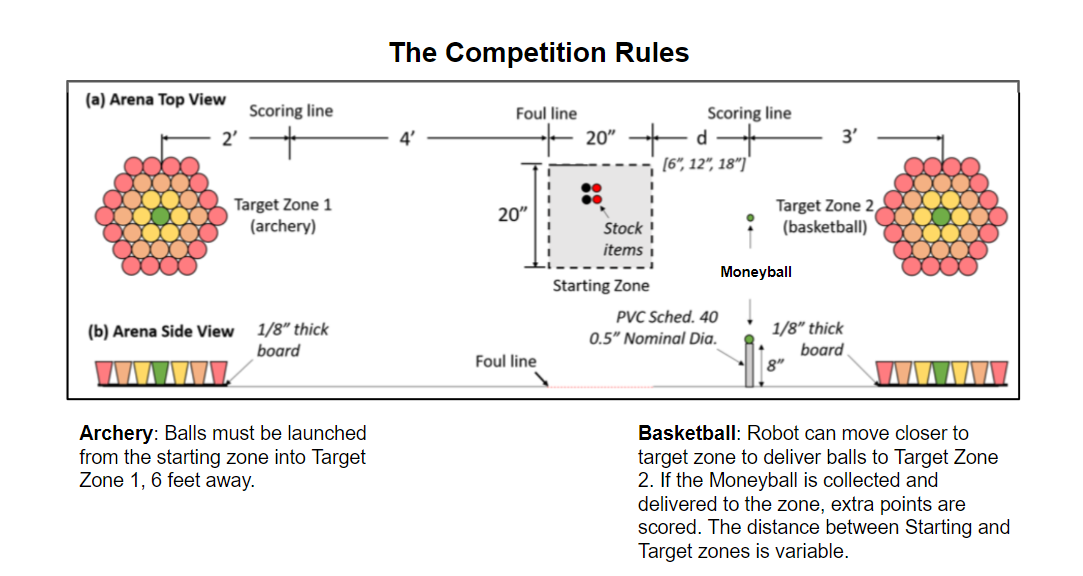

Over the course of a semester, I led a team of 5 to design, build, and compete with a robot tasked with delivering 2 ping pong balls to two sets of cup targets on opposite ends of an area, mimicking the Olympic events of archery and basketball. I headed development of 3 CAD design iterations, Arduino coding, and fabrication and testing of each design.

Design Selection

Several design tools were used to develop a number of possible robot designs. I drove team discussions to collaboratively develop and document customer & product requirements and evaluate potential solutions.

A House of Quality was used to translate customer requirements into engineering requirements, identify synergies and trade-offs between requirements, and quantify the relative importance of each engineering requirement. Prioritizing the engineering requirements allowed us to decide where to dedicate the team's design efforts.

A Specification Sheet was developed to define the product requirements and metrics for success.

A Function Tree was developed to break down all of the functions needed for the robot in competition.

A Morphology Chart was then created to brainstorm possible solutions for each function identified in the function tree.

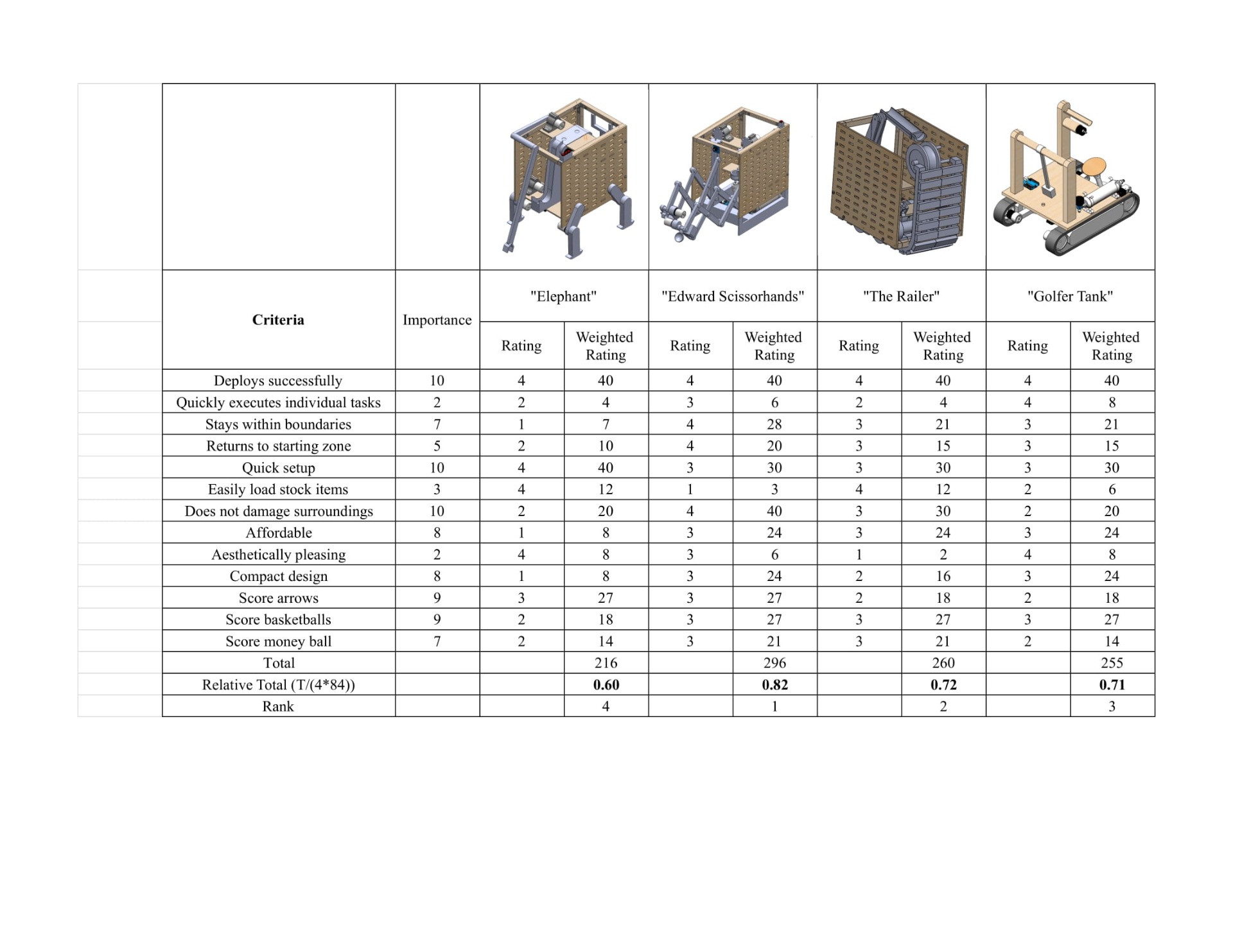

Picking solutions for each function from the Morphology Chart, I developed Elephant and Edward Scissorhands, 2 of 4 potential design solutions developed by the team.

Using a decision matrix to compare the effectiveness of each design at achieving each engineering requirement, Edward Scissorhands was selected by the team as the top design.

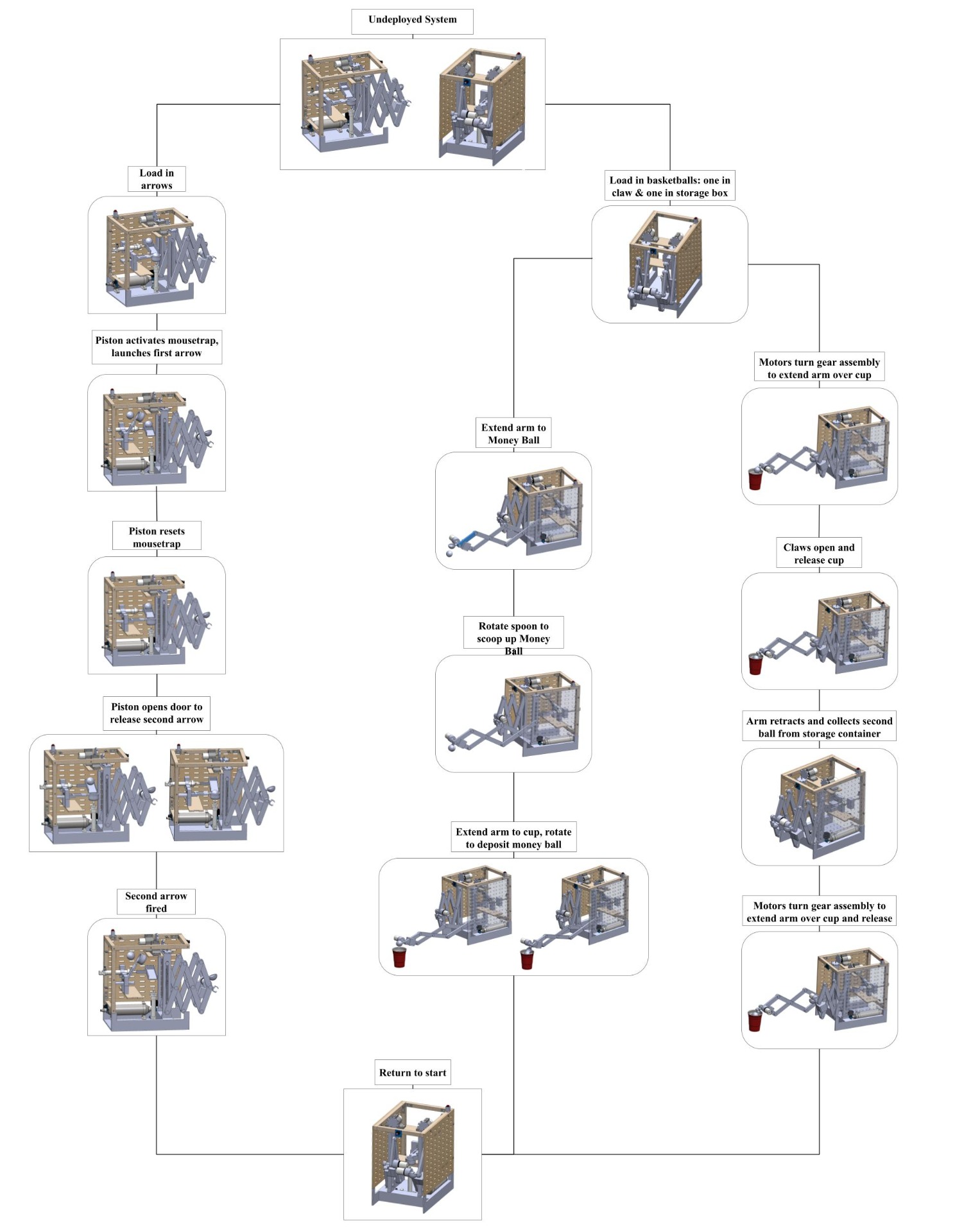

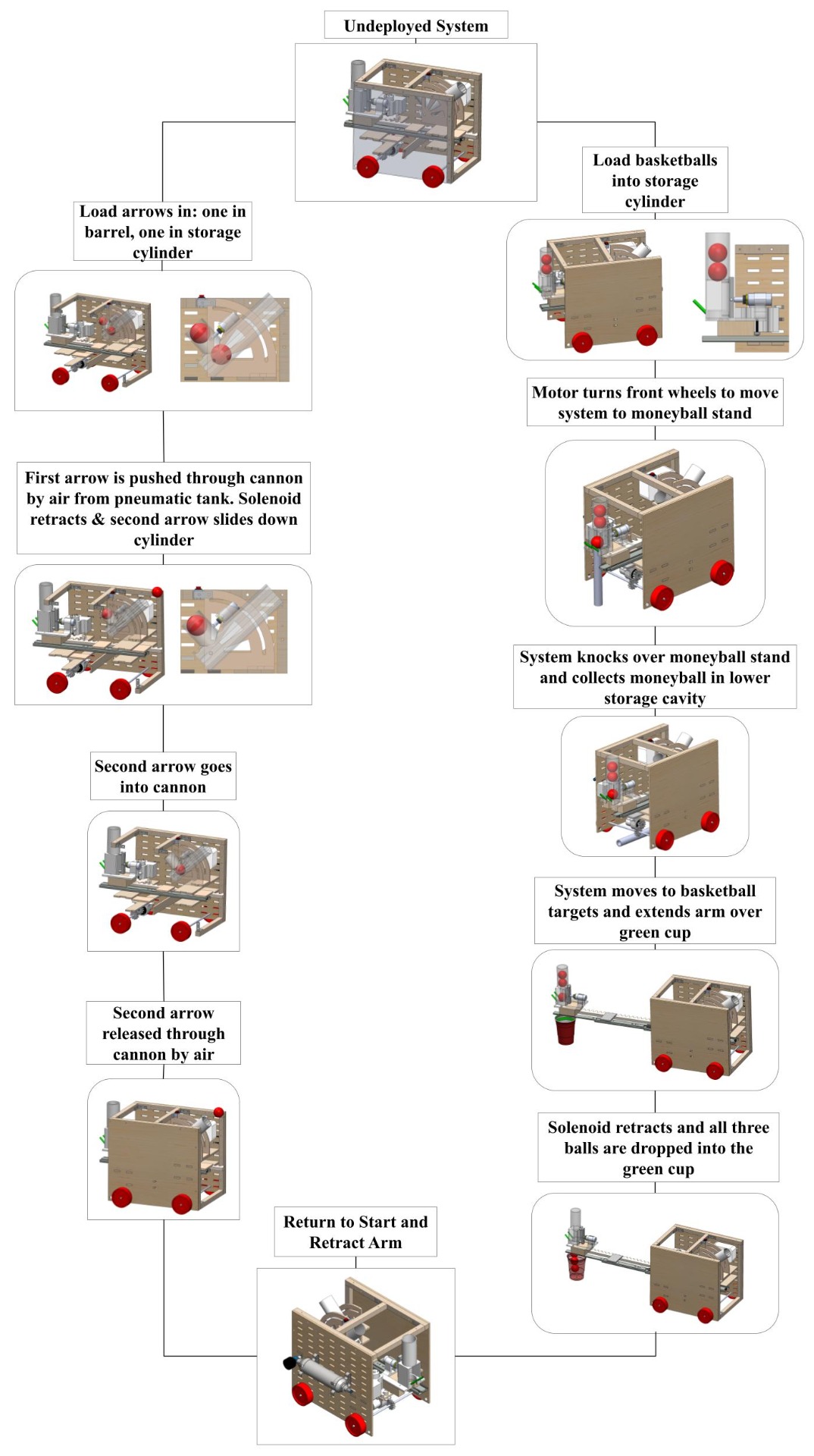

System Flowchart

I developed a system flowchart for the design to document how the design would execute each necessary function. I presented this flow chart and the design tools used to develop this design at a design review.

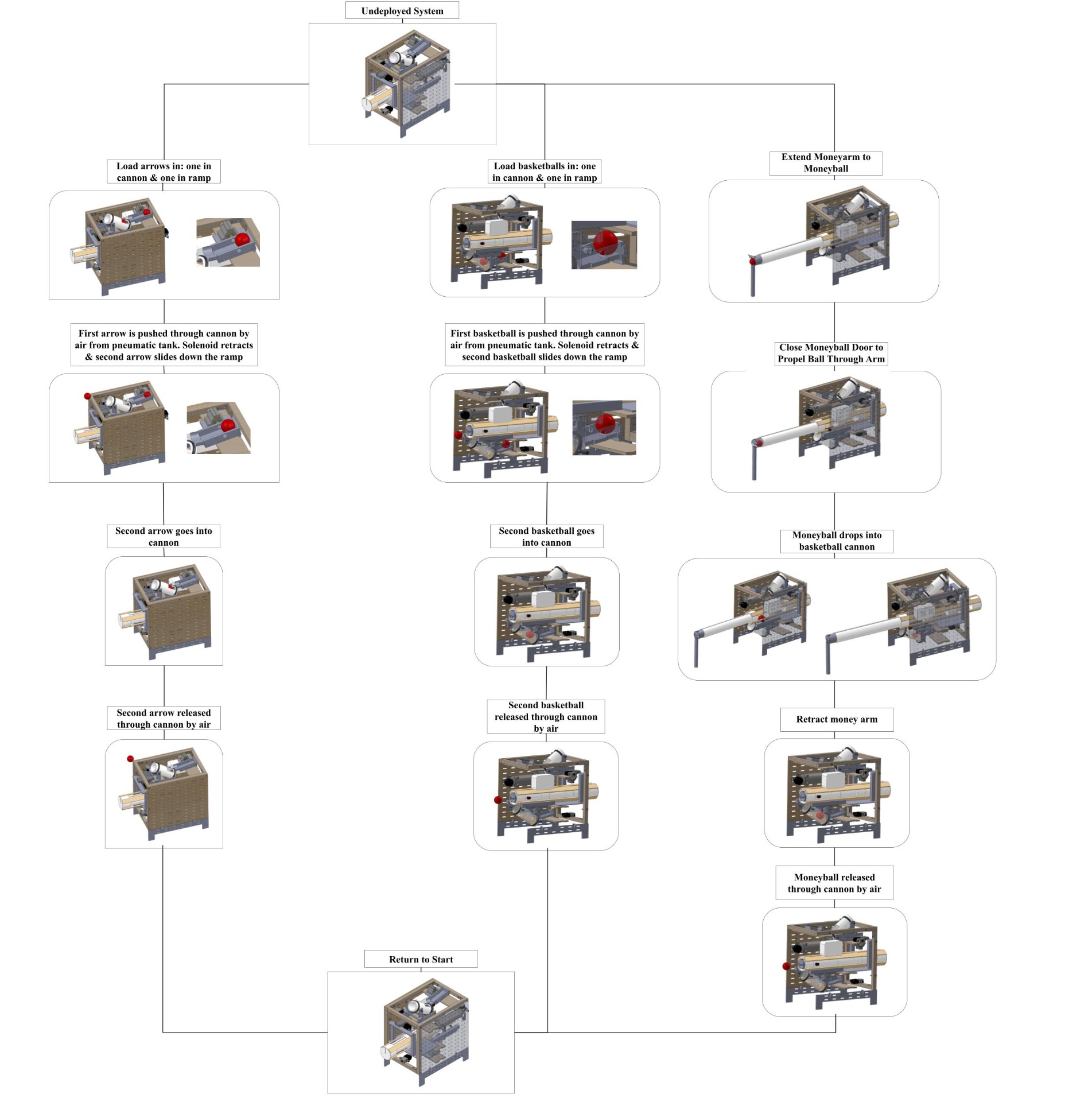

Fabrication

Examining the chosen design through the lens of design for manufacturing (DFM), it was clear that the design was highly mechanically complex and would be extremely difficult to manufacture given our resources. Thus I redesigned the mechanisms to reduce the number of components following a team discussion. I then created a system flowchart for the revised design.

Throughout the design process I headed CAD development and was responsible for keeping the system assembly up to date. I delegated CAD tasks to the team and designed components with manufacturability and assembly in mind (DFM, DFA)

I led the fabrication process of the robot design, creating files for laser cutting and 3D printing components. I also used shop tools like bandsaw/mitresaw, and other hand tools.

Mechanisms

Air Cannon

For for the basket ball and archery tasks, an air cannon is used to launch the ball to the desired target. One ball is preloaded into the cannon and another is stored in a ramp. The cannon was created from a PVC pipe and 3D Printed components. The ramp was laser-cut. A pneumatic tube is connected to the cannon, and air from a tank controlled through a pneumatic valve is used to launch the balls. Once the first ball is launched, I devised a mechanism where the solenoid in the ramp actuates to allow the second ball to roll into the cannon to be fired.

This video demonstrates the air cannon preforming well at the end of our first design sprint.

Moneyball Arm

To collect the Moneyball during the Basketball task, I designed an extending PVC arm. A string attached to both the inner and outer PVC pipes is wound around a motor such that the arm extends as the motor turns. This arm stops extending once it reaches the moneyball, and a string connected to the moneyball door pulls it closed. The ball is propelled down the arm where it falls into the cannon and is launched using the same cannon as the basketballs.

Design Refinement

Upon fabrication and testing of the robot, it became clear the air cannon was a mechanism well suited for the archery task, but higher precision was possible for the basket ball task by allowing the robot is allowed to move closer to the target. The PVC moneyball arm was also prone to failure to due the very high stress put on the string extending the arm.

After team discussion, I redesigned the system and created a revised final system flow chart to document how each mechanism preforms.

Mechanisms

Air Cannon

To increase the precision from the previous design, I designed a 3D-printed tube with the storage for the second ball built in to replace the PVC tube. The support structure was laser-cut. Preliminary testing of the design led to a discovery that a relief hole needed to be added near the entry point of the pneumatic tube to avoid a vacuum effect which would prevent the ball form firing.

This video demonstrates the robot firing the redesigned air cannon.

Extending Arm

To increase the repeatability of the basketball delivery, the air cannon from the previous iteration was replaced with an extending arm made from a draw slide moved by a rack and pinion driven by a motor. The moneyball capturing mechanism was integrated with this arm design. This design features a top storage cylinder where the two balls are initially loaded. The balls are kept in place using an extended solenoid connected to a fork, one prong of which holds the basketballs, and the other which will hold the Moneyball. As the robot moves, the Moneyball stand is knocked over by the Moneyball capturing cavity, and the front arms catch the ball and guide it to the storage cavity. Once the robot reaches the target, the arm extends over the green cup, where the solenoid is then retracted, and all three balls are deposited into the cup. The arm is then retracted.

This video demonstrates the robot preforming the basketball task using the extending are and ball capture mechanism.

Drive System

The drive train subsystem, was introduced to move the robot to the basketball target so that the arm can extend directly over the green cup. This system uses a motor and pair of gears to drive the front axle and wheels. Once the arrows are launched, this drivetrain moves the robot forward to the basketball targets. The arm is then extended, the balls are deposited, and then the drivetrain moves the robot back to the starting position.

Code Development

Competition

Reflection

If given more time to work on the robot, I would have further improved our performance by integrating a pressure regulator to the pneumatic tank used for launching the air cannon. In the final design, the pressure in the tank was filled by eye to a consistent pressure which led to some variability between trials.

I would also redesign the gears of the drive train to have less slip, as the large slip resulting from the spaced out gear teeth led to the final positioning of the robot having a relatively large range depending on how the teeth were positioned relative to each other at the beginning of a trial. As a result, the final positioning of the robot was not precise enough to guarantee with high probability that the robot would return to the start box perfectly at the end of the trial. I brought this problem to the attention of my team and after a team discussion, we decided to minimize risk by not attempting this task in the competition as over shooting the start box would result in 0 points for the entire trial.

Finally, if there was an opportunity to obtain a consistently preforming IR sensor, I would have integrated this into our control system to have the robot stop moving once it saw the taped regions marking each zone rather than have a purely time based system. This would have allowed the robot to preform well independent of if there were small errors in the target locations of the competition track.