Wall-Climbing Robot

Product Design | Problem-Solving | First Principles Engineering

Problem Description

This project is part of a design challenge to ideate a solution based on the prompt:

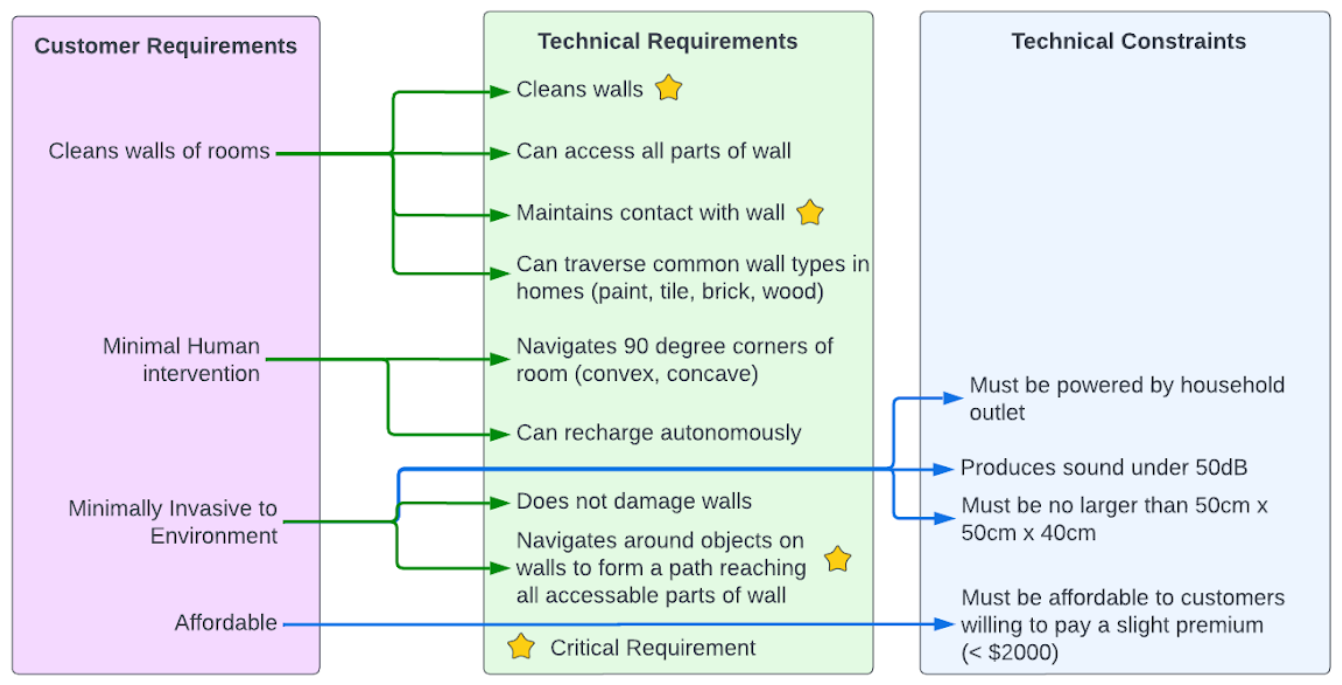

Identifying Customer and Technical Requirements

Target customers for this wall-cleaning robot product are people with allergies or asthma who are sensitive to dust on walls, smokers looking to remove smoke residue from their walls, and tech-savvy homeowners looking to maintain the walls for their home. Since this device would be routinely used in the home, customers want a product that is noninvasive to their home and needs as little human intervention as possible. The following technical requirements and constraints were identified based on the needs of these target customers, where requirements are factors required to achieve a desired product function and constraints are limits on the solution which cannot be changed. Critical requirements were identified based on their importance to the core product function and difficulty of implementation.

Brainstorming and Evaluating Potential Solutions

Several solution methods for the critical technical requirements were brainstormed and researched. Solutions were evaluated based on results from studies on the technology or existing robotic cleaning solutions like the Roomba and conclusions drawn based on the extent to which each solution meets the needs of the customer.

Maintaining Contact with Walls

Propulsion: Using drone-like propulsion would eliminate the challenge of "sticking" to the wall, which other methods face, making it suitable for uneven surfaces and nearly every type of wall. However, the use of rotary blades is noisy and creates a safety hazard, especially for families with children or pets, making it invasive to the environment.

Gecko Inspired Feet: This technology is still in early development which makes it poorly suited for a consumer product due to cost of production. Existing demonstrations of this technology behave poorly on dusty, wet, and uneven surfaces making it unsuitable for use on dirty or textured walls.

Vacuum: Vacuum adhesion is a well explored method for reliably sticking to walls, however, it is sensitive to irregularities in surfaces. It would likely be suitable for smooth walls but not for tile or paneled walls which are common in homes. Vacuums also require a lot of power, which would result in short battery life or require a large and heavy battery.

Electroadhesion: Electrostatic adhesion has been demonstrated in a study by SRI International to be effective on both uneven and dusty surfaces, making it suitable for all common wall types [1]. It has also been demonstrated to have a very low power consumption, reducing the need for a large on-board battery.

Wall Mounted: While this method would be cheaper and more energy efficient than the other alternatives, the wall mounted mechanism would need to be installed in every room where the device is used which is too invasive for the target customer.

Suction Cups: This method is advantageous because the suction cups are completely passive which reduces the energy consumption of the robot. However, suction cups are very sensitive to surface texture and dust making it unsuitable for this application.

Of all of the leading wall climbing technologies, electroadhesion is the most suitable for a wall-cleaning application as it works regardless of dust or irregularities on a surface, and has a low power consumption.

Cleaning Walls

Vacuum: Vacuums are common in existing home cleaning robots. It would be effective at removing dust from walls and containing it. However, it would not remove stuck on debris or coatings like smoke residue.

"Lint Roller": Using a sticky sheet would be effective at removing only dust from walls. It has a low energy cost but would be extremely wasteful as the amount of the sheet needed would be equal to the area of the wall, making it infeasible for this application.

Rotating Sponge: Rotating sponges are an effective solution used by existing mopping robots. Most sources recommend cleaning walls with a cleaning solution in circular motions which is achievable with this method. However, a sponge may dislodge dust from walls rather than collecting it, resulting in more dust in the air.

Rotating Duster: A rotating duster could be effective at removing dust from walls however this dust would end up in the air, making it unsuitable for customers with dust sensitivities.

Water Sprayer: Most sources recommend cleaning walls with a solution, which could be provided by the water sprayer, however the robot would need a water storage receptacle, increasing the weight of the robot.

The best solution to cleaning the walls would be a combination of methods to first eliminate the dust on the wall, then deep clean the walls using water or a cleaning solution. As a vacuum is the only feasible solution for removing dust from the environment entirely, it is important that it is present in the final solution.

Navigating Around Obstacles to all Accessible Wall Space

Infrared Sensor: Existing autonomous cleaning robots like the Roomba use IR sensors to detect objects around them. This sensor offers a large detection distance and range making it well suited for detecting walls around the robot.

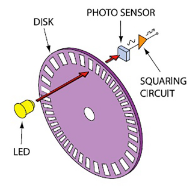

Encoder: Once location data of obstacles is determined by other means, an encoder on each of the robot's wheels allows it to track how far it has moved, so it can navigate around these obstacles. An encoder can also be used to compile a map of the room during the first run, so in future runs it can optimize a more efficient path.

Bump Switch: A bump switch is used by existing cleaning robots to detect collisions with smaller obstacles that have not been detected by the other sensors. These sensors are advantageous because they are very cheap and require little energy.

Laser Triangulation Sensor: This sensor can sense the exact distance of objects ahead of it. However, it typically has a small viewing distance and very small viewing range, making it poorly suited to the task of detecting obstacles surrounding the robot.

LIDAR: LIDAR sensors are very expensive and the level of resolution of the environment they provide is not necessary for this application. They are also typically heavier than other sensors and require more energy.

To navigate the environment and detect walls and obstacles, the best solution would be a combination of IR sensors, encoders, and bump switches.

Addressing Key Challenges

Traversing the Environment:

To clean an entire room continuously, the robot must navigate both convex and concave corners. To simplify this problem while accommodating the corners in the vast majority of homes, all corners are assumed to be 90 degrees. To overcome this challenge, 3 potential solutions were identified:

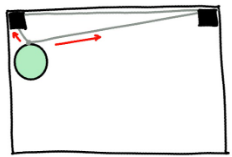

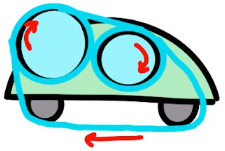

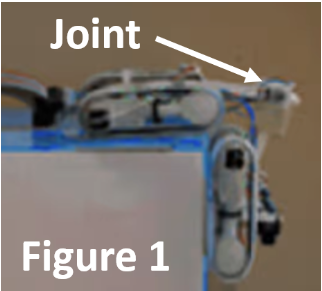

A central joint could be integrated to allow the robot to fold around corners as demonstrated in Figure 1 [2]. This however, requires essentially the creation of two stand alone robots joined by an actuated hinge. This would more than double the cost and complexity of the system and increase the energy used.

When a corner is detected, the robot could dismount the wall onto the floor and navigate to the next wall. This solution is the simplest to implement as it has been demonstrated successfully with many existing wall climbing robots. However, it creates problems when there is no available floor space to access the next wall as is common in a furnished home.

Instead of navigating to the next wall using the floor, the robot could adhere to the ceiling to navigate around the corner. This avoids problems with there being no available floor space to access the wall.

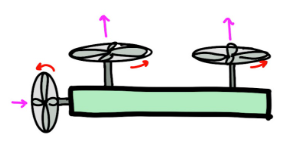

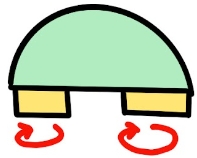

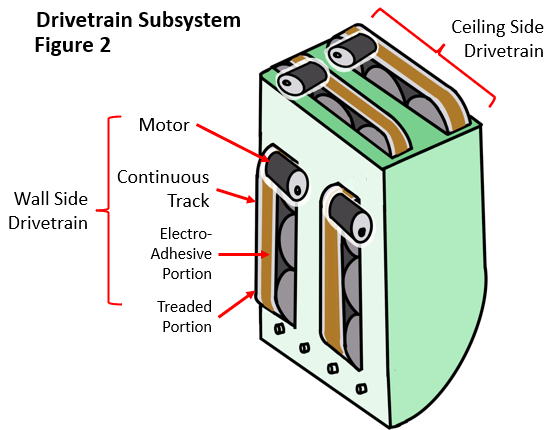

Of these three possibilities, the solution of traveling along the ceiling to the next corner best addresses the customers' need to have all walls in a room cleaned continuously. This solution keeps costs reasonable while avoiding the addition of an invasive floor space requirement which may force users to rearrange their furniture. The proposed drivetrain subsystem for the robot is shown in Figure 2.

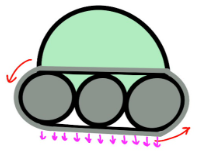

Two identical drivetrains exist on the robot. An electro-adhesive continuous track on the wall-side allows the robot to navigate on the walls during normal operation, while the ceiling-side track allows it to navigate on the ceiling while handling corners.

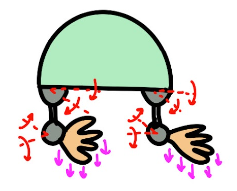

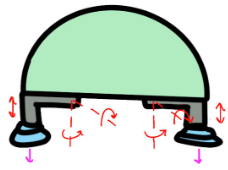

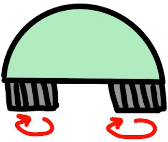

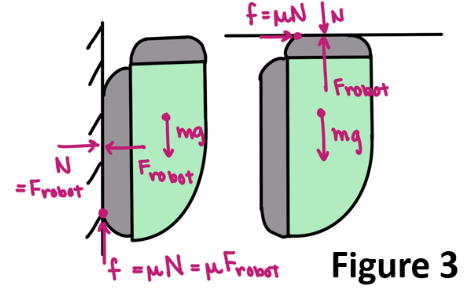

The forces experienced by the robot are shown in Figure 3. The outer edges of the tracks are treaded to provide the friction needed to prevent slip. This portion is made of soft rubber to maximize the coefficient of friction with the wall. This high coefficient of friction minimizes the electrostatic force needed to keep the robot from falling. The central electroadhesive portion provides the electrostatic force needed to keep the robot from tipping off the wall.

Each track has its own motor to allow the robot to turn by creating a speed differential. Once the robot reaches a corner, it will travel to the ceiling and activate the ceiling-side drivetrain while deactivating the wall-side drivetrain. It then navigates around the corner, positioning itself against the wall. The wall-side drivetrain reactivates while the ceiling-side deactivates, completing the corner transition.

For the drivetrain, a high speed motor is not necessary as the robot should move slowly along the walls to ensure ample cleaning time. Thus, a reversible DC brushed motor is sufficient and fulfills the need for a light, efficient, and affordable motor.

Mapping the Environment:

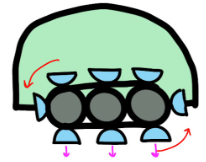

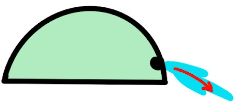

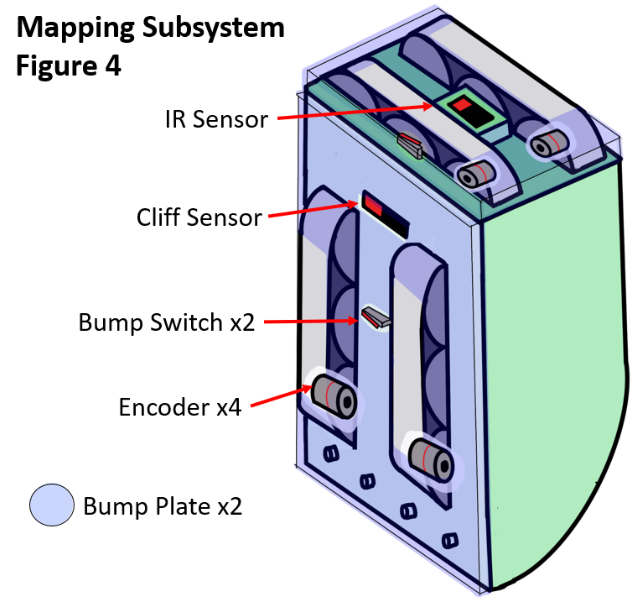

To map the environment, multiple sensors are needed to detect the surroundings of the robot as shown in Figure 4. To sense walls, an IR sensor is located on the top of the robot. When the robot turns horizontally along the wall, the sensor detects any upcoming concave corners.

To detect upcoming convex corners, an IR cliff sensor is located on the leading edge of the wall-facing side. This sensor detects the absence of a wall as the robot tries to move forward, indicating a convex corner.

To detect objects on the wall as well as ensure the robot is in contact with the ceiling or wall before switching drivetrains when traversing a corner, a bump switch on the top and wall-facing sides is used to detect collisions with objects. If the IR sensor confirms the presence of a wall, the robot will traverse the corner. However, if the IR sensor does not detect a wall, this means the robot has encountered an obstacle and will navigate around it. To ensure that a collision at any point along the entire face is detected by the bump switch, two bump plates, which are mounted on the bump switches and in-line with the continuous track, translate any collisions to the bump switch.

Encoders are used on each continuous track to locate the robot's actual position, which is crucial for traversing corners. It will also allow the robot to generate a map of the space after one run, enabling it to use this map again in future runs to optimize its path. This will require a powerful on-board microcontroller.

Cleaning the Environment:

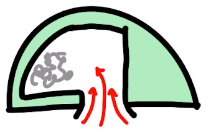

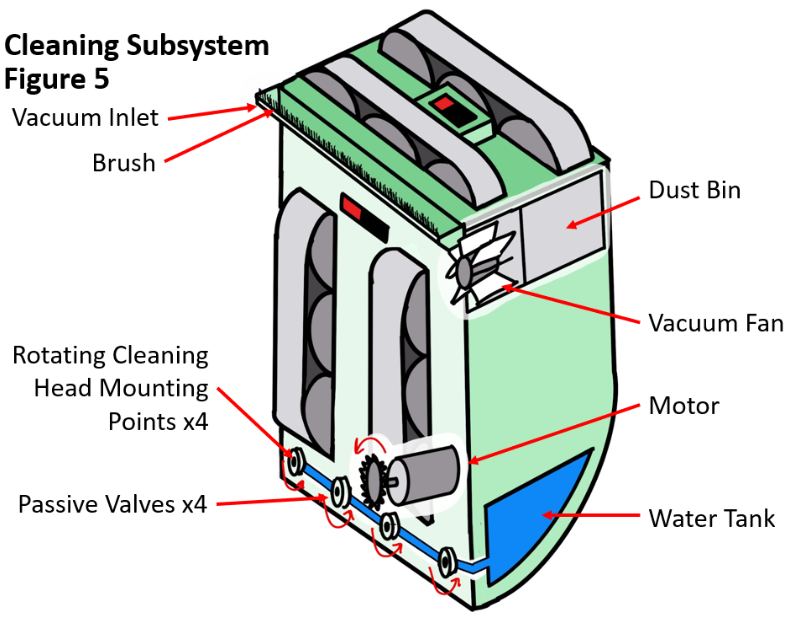

Several sources on cleaning walls recommend first removing dust from the walls and then washing the walls with water or a cleaning solution in circular motions.

To first remove dust from the wall, a vacuum inlet on the leading edge of the robot is used as shown in Figure 5. A brush is used to agitate any settled dust to improve collection. This vacuum is created by a high speed fan, and the debris taken in is deposited in a removable dust bin.

To then clean the walls with water, removable cleaning heads are mounted onto four rotating mounting points which are spun in unison by one high speed motor and a gear-train.

To supply water to the heads, each head is connected to a removable water tank by a passive valve which slowly releases water onto the head. Replaceable cleaning heads are attached to the mounting points so the user can select the ideal head material for their walls (microfiber, sponge, etc.) or clean the heads once they are dirty.

Powering the System:

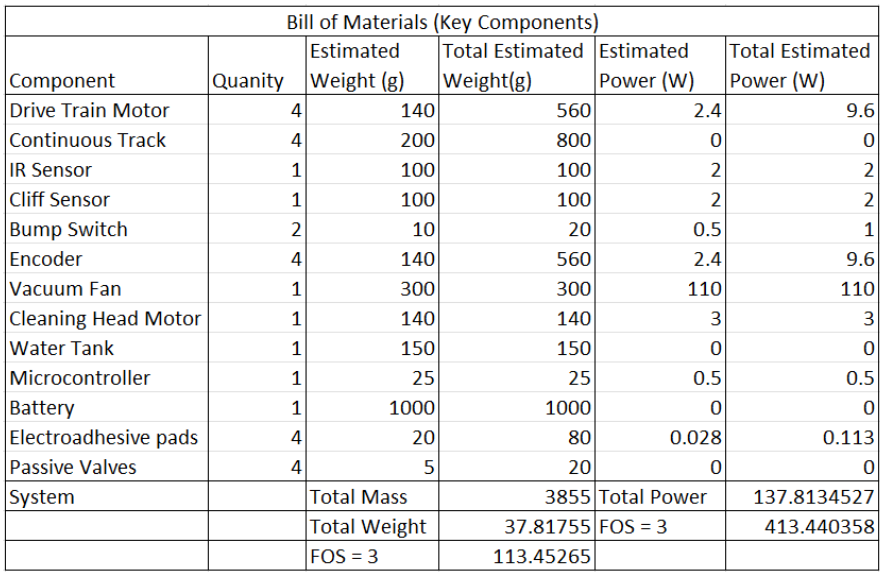

To determine the energy requirements of the designed system and ensure its feasibility, the energy requirements for each component must be estimated. While the energy requirements for every other powered component can be estimated by researching typical energy requirements of these components, the energy required by the electroadhesive pads must be calculated.

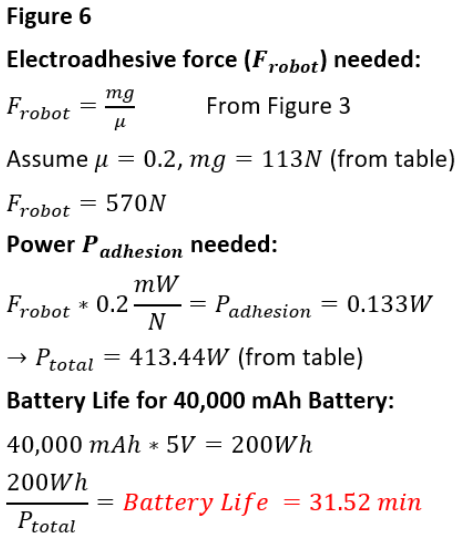

The energy needed by the electroadhesive pads is proportional to its weight. An estimate for the weight of the system is calculated as 113N including a factor of safety of 3 since this is a rough estimate. This was found using typical weights for these components as shown in the table on the next page. For an electro-adhesive system, SRI International determined the energy needed to be 0.2mW/N [1]. Assuming a 5V system and a conservative coefficient of friction of 0.2 between the rubber treads and the wall, the power needed by the electroadhesive pad is 0.13 W. Adding this to the estimated power required by the other active components, the total needed power for the system, with a factor of safety of 3, is 413W. In this calculation, the fan creating the vacuum had the largest contribution but is necessary to ensure dust removal for customers.

Other consumer cleaning-robots have a battery life of around an hour. Since this wall cleaning robot is more affected by the trade-off between battery-life and battery-weight since it traverses walls rather than floors, a shorter battery life of 30 minutes is targeted to provide enough power to clean a significant portion of the wall before recharging while limiting the energy needed to support the robot's weight.

By selecting a 40,000 mAh rechargeable battery, the robot has a battery life of just over 30 minutes as calculated in Figure 6. A battery of this size is feasible to have on-board as it weighs roughly 10N and is relatively small in size, fitting well within the size constraint of the system.

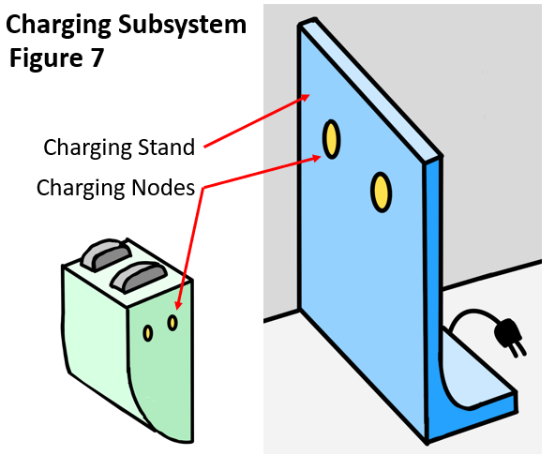

To recharge the robot with minimal intervention from the customer, a docking station is designed as shown in Figure 7. At this charging stand, nodes from the stand transfer power to corresponding nodes on the robot. To dock, the robot navigates along the wall to the known position of the charging stand. When the back face of the charging stand is aligned against the wall, the nodes of the robot and charger will make contact.

When the robot begins running low on power, it stores its current position and navigates back to the charger. Once it is fully charged, it returns to its last position and continues cleaning the wall. Once the wall has been completely cleaned, it docks at the charging stand to complete the cleaning cycle.

Product Summary

Technical requirements and constraints for this wall-cleaning robot product were identified by breaking down the needs of the target customer. Of these requirements, the most crucial were used to drive the direction of the design. By researching existing technologies and similar products, optimal solution methods were determined. These methods were combined to create robot subsystems which accomplish core product functions. In the design of these subsystems, the other technical requirements were addressed. Sketching and some mathematical analysis were used to ensure the feasibility of the solution.